Amine Functional Silicone Fluids

Amine Functional Silicone Types

About Amine Functional Silicone Fluids

Amine functional silicone fluids combine the polarity of amines with the advantages of silicone fluids. The polarity of the alkyl amine gives the silicone an affinity for metallic and polar substrates. This quality is advantageous in release agent and lubricant applications where the extra substrate affinity caused by even a trace of amine functionality leads to enhanced lubricity and durability. Additionally, amines can be used as catalysts to promote moisture curing of alkoxy groups in Amine/Alkoxy functional silicones and they can also be useful in crosslinking reactions.

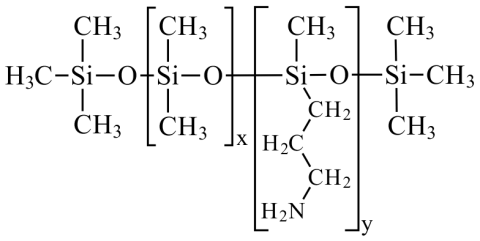

Pendant Amine/Dimethyl Copolymers

Randomly Distributed Amine-Alkyl/Dimethyl Copolymers

Genesee Polymers Corporation manufactures three Amine-Alkyl/Dimethyl copolymers with the following general structure where the blocks are randomly distributed:

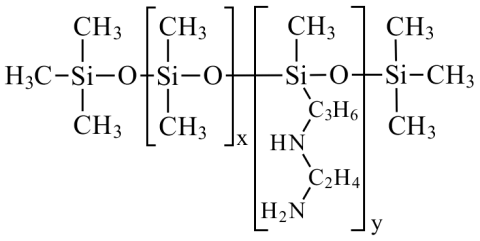

Polar Amine/Alkyl Functional Blocks

In addition to the pendant amine copolymers listed above, Genesee Polymers also offers a wide range of more polar diamino/alkyl functional blocks for applications where a stronger interaction is required with a given substrate. These fluids have the following general structure where the copolymer blocks are randomly distributed:

Amine/Alkoxy End-Blocked Silicones

When Amine and Alkoxy functional groups are combined on the end of a silicone, the Amine catalyzes hydrolysis and condensation of the alkoxy groups. The result is a novel moisture curable system that produces a soft, flexible film useful for release coatings or any application that requires a water resistant, protective coating. Genesee Polymers Corporation manufactures two types of silicones in this category, rapid cure and slow cure. The rapid cure products react with ambient moisture in the air and form a cured film within minutes. The products in this category are listed from fastest curing rate to slowest curing rate. The slow cure products thicken very slowly on exposure to moisture without forming a completely cured film.

Amine Functional Paintable Silicone Fluid

GP-7100, also listed under paintable release agents, is amine functional. The amine functionality gives it a higher affinity for mold surfaces and the absence of dimethyl silicone units makes it compatible with most paints and coatings.

| Product | Molecular Weight (Calculated) | Viscosity (cPs) @ 25°C | Amine Number * |

|---|---|---|---|

| GP-7100 |

7800 amu

|

1250 cP

|

13

|

| * milliliters of 0.1N HCl needed to neutralize 10 gms of product | |||